The yarn, starting from the raw material and during all stages of the production, is regularly checked in our laboratory through a series of qualitative tests with the aim of analyzing the characteristics (resistance, regularity, titration, percentage of humidity, twists, etc.) and to ensure the quality of the finished product.

R&D and Quality Control

The yarn is regularly checked through a series of qualitative tests with the aim of analyzing the characteristics and to ensure the quality of the finished product.Eco-Sustainability

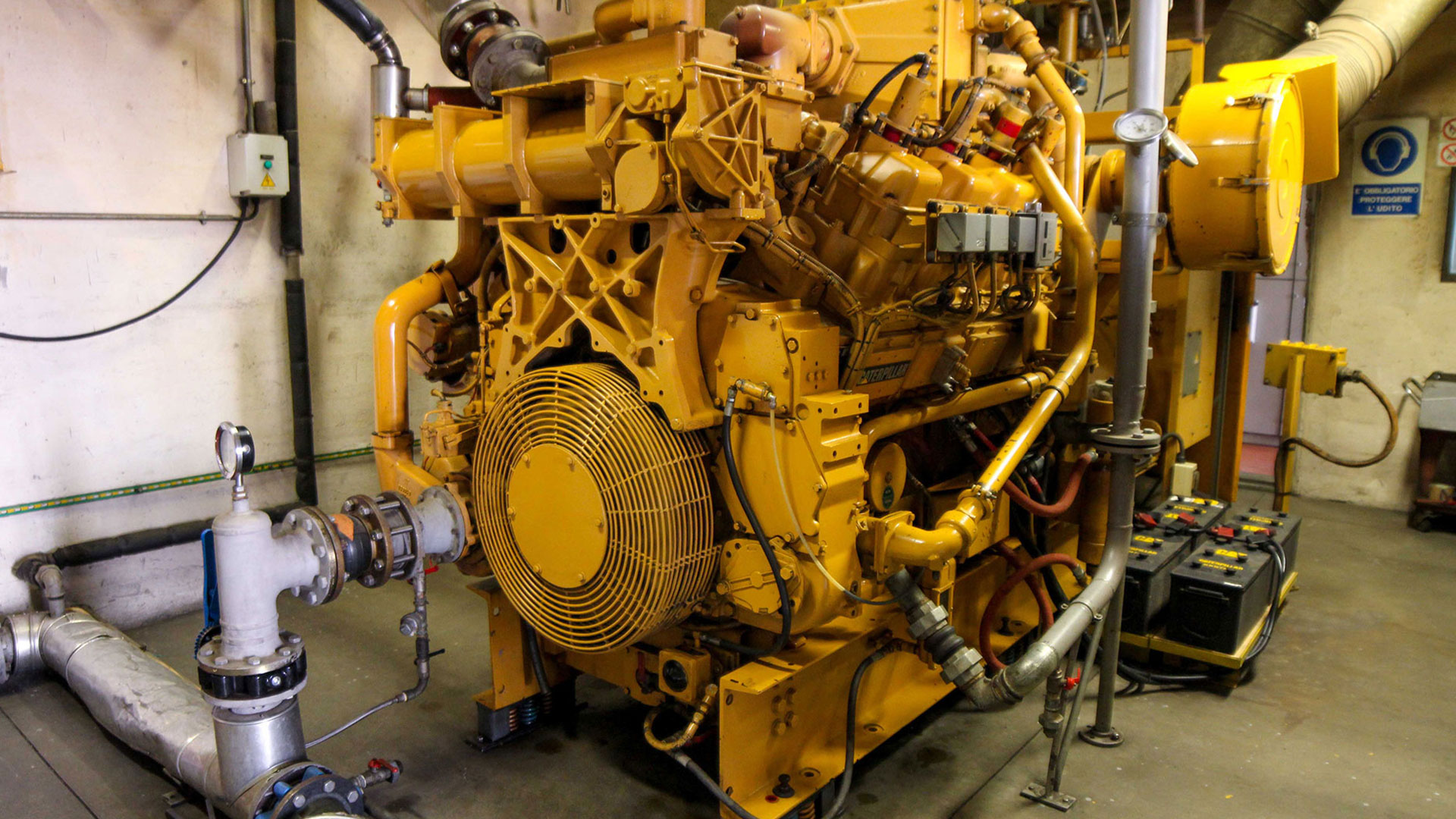

a photovoltaic installation and a cogeneration plant, the first in Italy to be designed and built for a company.For about 20 years Filatura Lacfimi, in parallel to textile production, has focused on another objective: to be a “green”company. This commitment results in the presence of a park-garden, a photovoltaic installation and a cogeneration plant, the first in Italy to be designed and built for a company.

Cogeneration is realized by using a thermal power plant to recover and convert the steam produced during the production process; this installation brings many positive aspects, that are reflected on the company:

Environmental benefits like air pollution reduction and less dependence from fossil sources; energy advantages concerning the recovery of unused thermal energy, a lower consumption of fuel and a higher energy efficiency and, consequently, economic advantages with a lower cost for the production of energy.

Since the end of 2016 Filatura Lacfimi is an active member of Textiles and Health association that works to prevent and fight against the market diffusion of harmful product to the health of consumers.